Say hello

info@werover.com

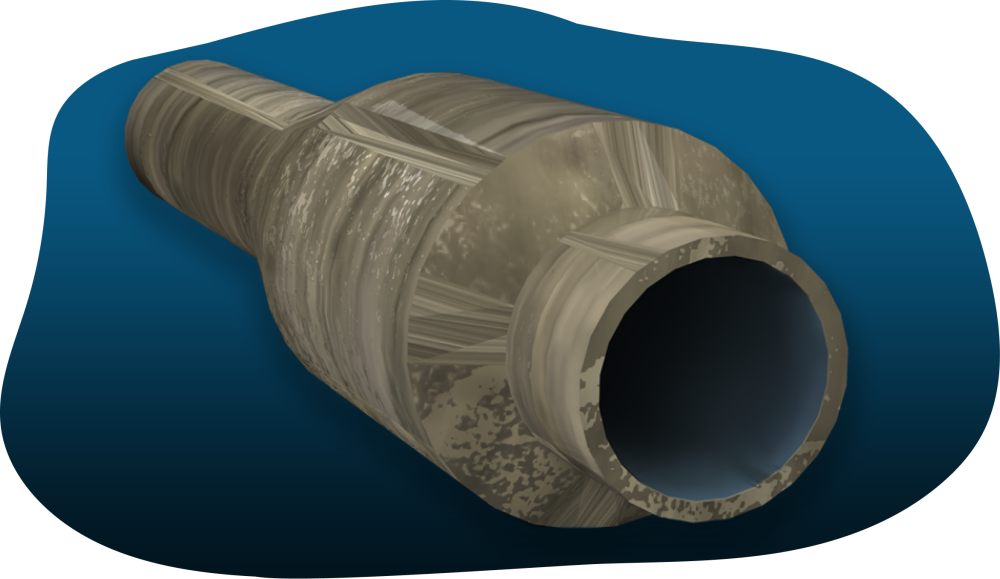

When the water in a hydropower plant is drained, the workers detect the cracks by walking with the sensors and cameras in the tunnels. The water discharged through the tunnel causes hydrostatic pressure. This creates a risk of collapse in the tunnels which is very dangerous for the people and the tunnel itself.

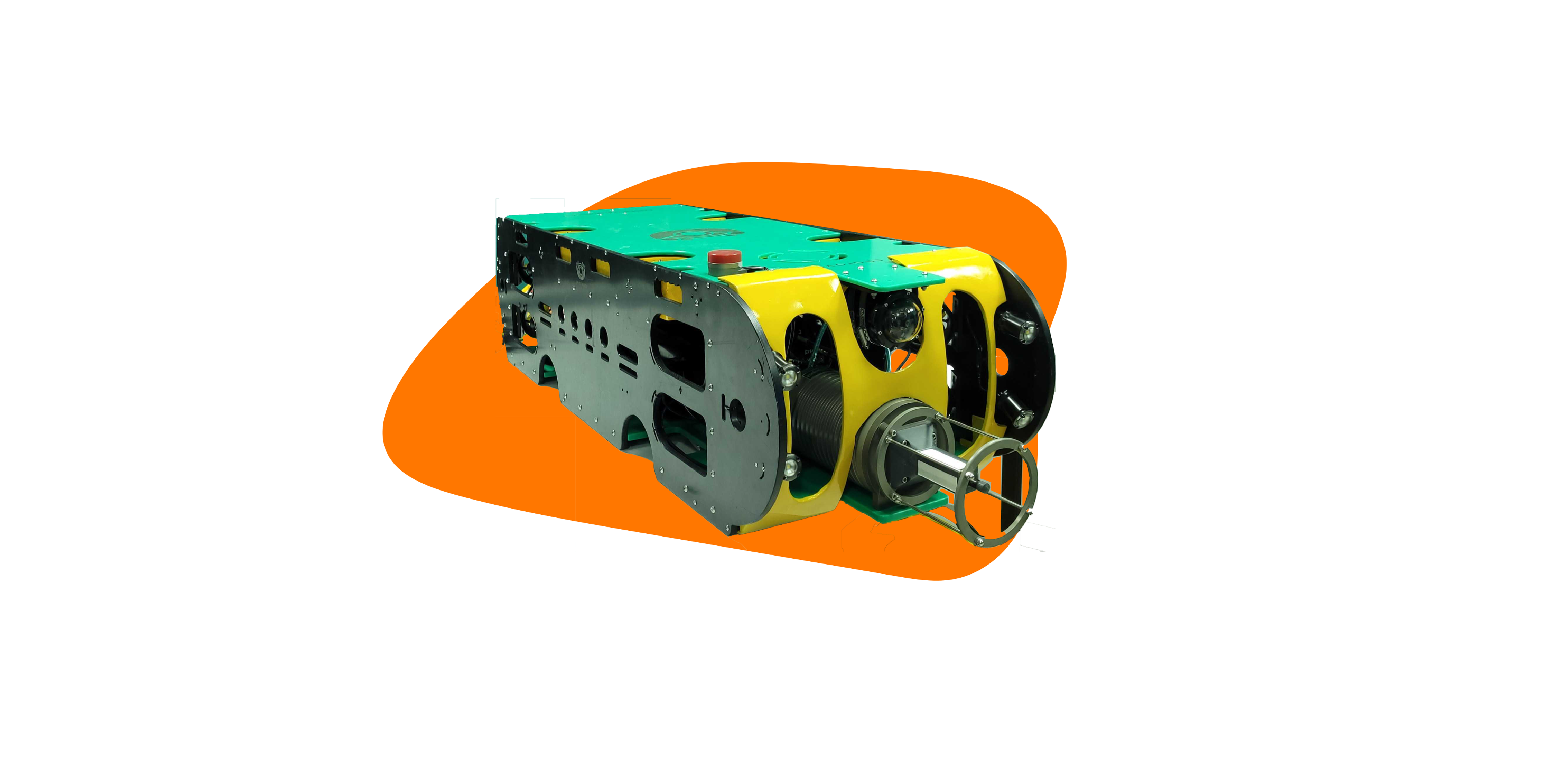

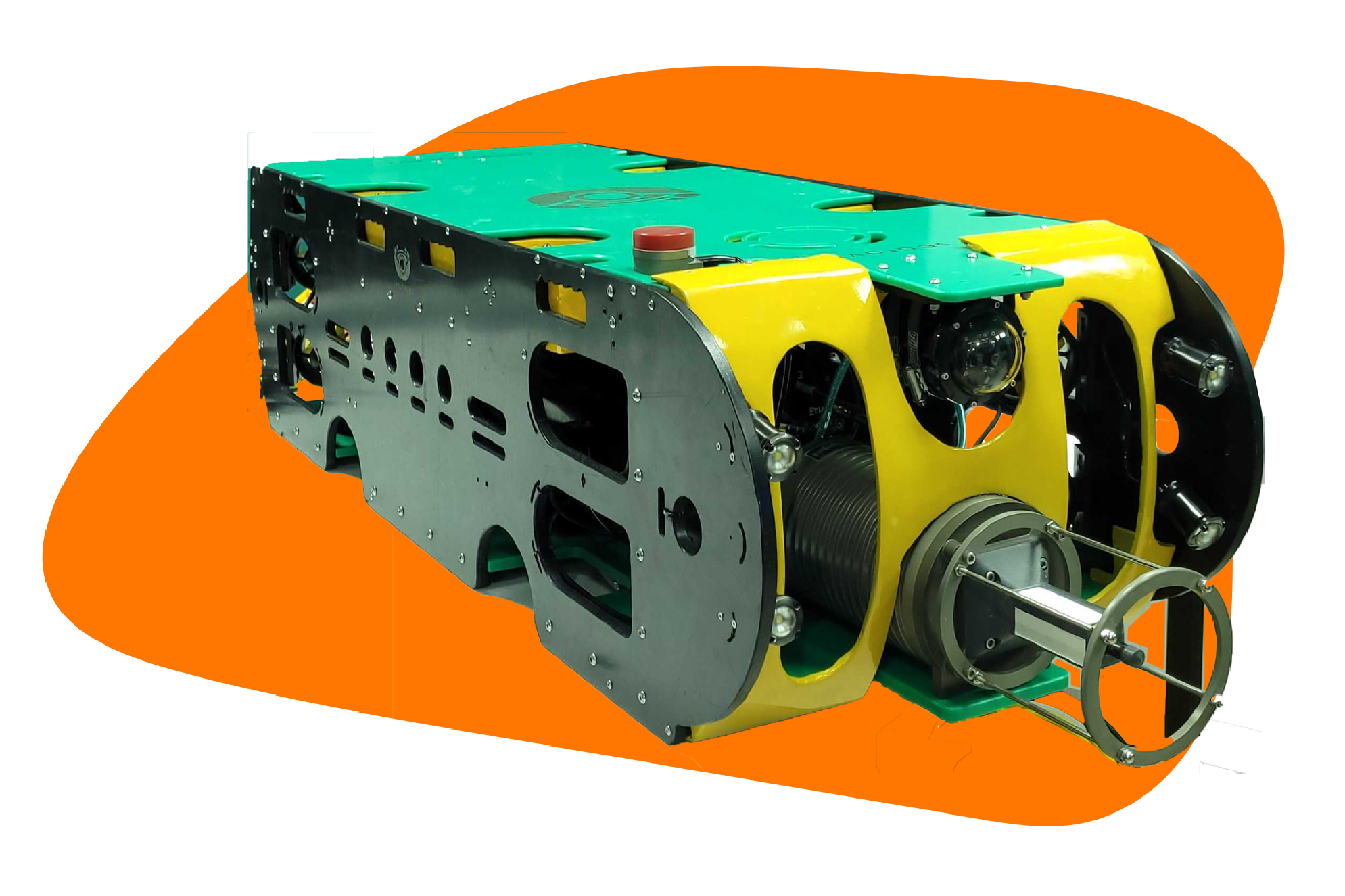

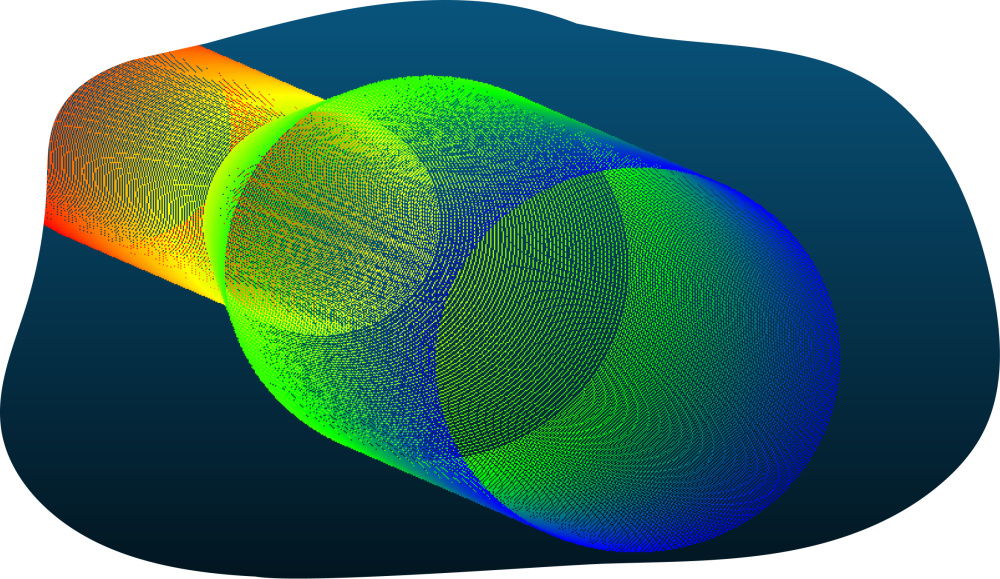

In addition to all these risks, the visual operation of a hydroelectric power plant is very time consuming. The weeks of visual inspections cause energy and high cost losses. As Werover we are working on modeling and damage assessment of the hydropower plants.